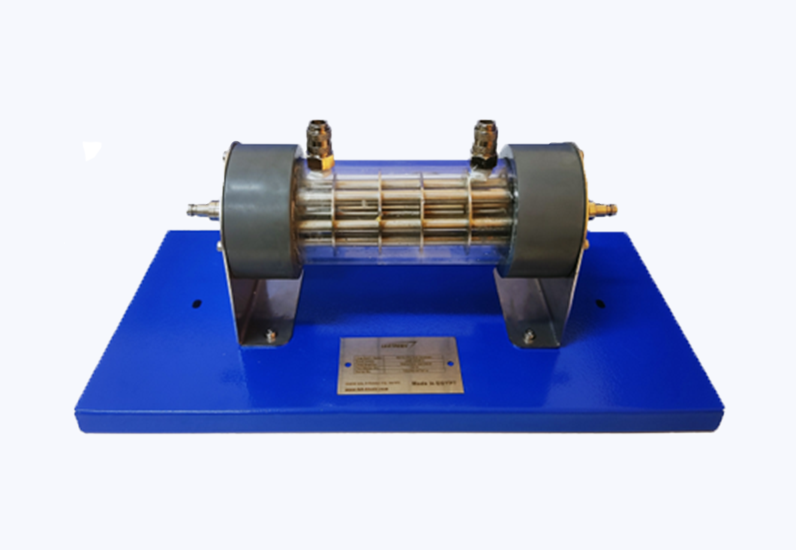

The Labtronic Shell & Tube Heat Exchanger (LT-HT110) is a robust and versatile educational tool designed to demonstrate the principles and operation of shell and tube heat exchangers, which are commonly used in industrial applications. The unit consists of multiple tubes housed within a transparent shell, allowing for clear observation of the heat transfer process. Baffles are incorporated within the shell to enhance heat transfer efficiency by directing fluid flow and promoting turbulence.

When used in conjunction with the Heat Exchanger Supply Unit (LT-HT107), hot water flows through one set of channels within the shell and tube heat exchanger, while cold water flows through another. The flow rates of both fluids can be precisely controlled using the flow control valves provided with the supply unit. Quick release fittings ensure that the setup and operation of experiments are straightforward and user-friendly.

Temperature sensors and flow sensors are integrated to measure the inlet and outlet temperatures as well as the flow rates of the fluids, providing accurate data for analysis and study.