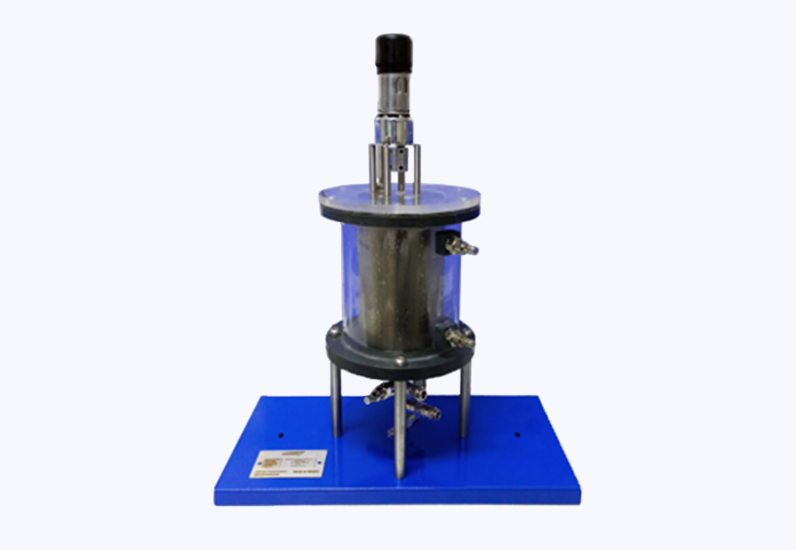

The Labtronic Stirred Tank with Double Jacket and Coil (LT-HT111) is a versatile heat exchanger designed for educational and experimental purposes. This unit uses a main tank equipped with both a jacket and a coil tube, allowing the transfer of heat between two fluids. It is particularly effective in demonstrating how the stirring action enhances heat transfer efficiency.

When used in conjunction with the Heat Exchanger Supply Unit (LT-HT107), this unit allows for detailed experimentation with the heat exchange process. The main tank is typically filled with cold water, while hot water circulates either through the jacket surrounding the tank or through the coil tube inside the tank. The integration of a stirring machine ensures thorough mixing, resulting in improved heat transfer.

Temperature sensors and flow sensors are included to measure the inlet and outlet temperatures, as well as the flow rates of the fluids, providing essential data for analysis.